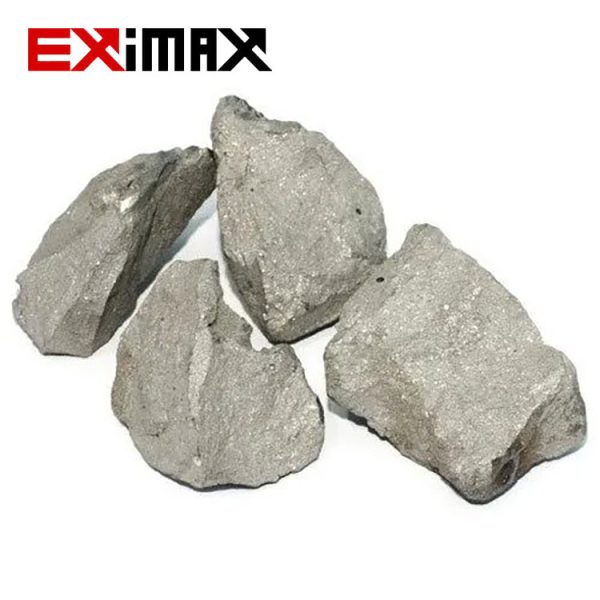

Ferrotitanium is a ferroalloy, which is an alloy consisting of iron and titanium, typically containing between 10-20% iron and 45-75% titanium, along with a small amount of carbon.

Titanium is utilized in the steelmaking process for various purposes, including deoxidation, grain-size control, carbon and nitrogen regulation, and stabilization. In steelmaking, titanium is introduced in the form of ferrotitanium due to its lower melting temperature and higher density compared to titanium scrap. The primary consumers of titanium in the steel industry are producers of interstitial-free, stainless, and high-strength low-alloy steels.

Ferrotitanium is commonly produced by melting titanium scrap together with iron or steel using induction. However, it can also be produced directly from titanium mineral concentrates.

| Brand | Chemical Analysis | |||||||||

| Contents ( wt.% ) | ||||||||||

| Ti | Si | Al | C | P | S | V | N | Cu | Fe | |

| FeTi | 65-70 | 0.5 Max | 0.5-4.5 | 0.10-0.20 | 0.02 Max | 0.02 Max | 1.5-2.00 | 0.2-0.4 | 0.10 Max | Balace |

| *Size and Packing can be adjusted by customer requirement | ||||||||||